What are the different types of SCADA alarms?

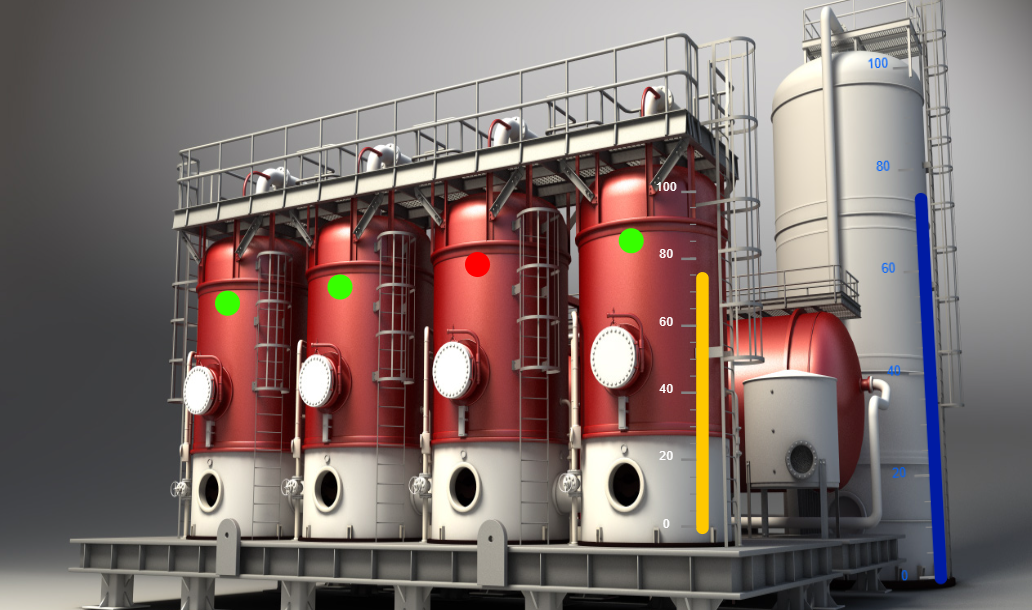

In industrial settings, SCADA (Supervisory Control and Data Acquisition) systems play a critical role in monitoring and controlling processes such as manufacturing, water treatment, and power generation. One of the most important functions of a Alarm Management is the ability to detect and report issues through alarms. SCADA alarms alert operators about system deviations, potential failures, or other events that need attention to ensure the safety and efficiency of operations.

In this article, we will explore the different types of SCADA alarms, their levels, and how they help maintain system integrity.

What Are the Different Types of SCADA Alarms?

SCADA alarms are categorized based on their severity and the nature of the problem they indicate. Understanding the different types of alarms helps operators prioritize their responses and address the most critical issues first. Below are the main types of alarms commonly found in SCADA systems:

- Process Alarms

Process alarms are the most common type of SCADA alarms. They indicate deviations in process variables such as temperature, pressure, or flow rate. These alarms help operators maintain the system within desired operating ranges. For example, if a pressure valve exceeds a set threshold, the system will trigger a process alarm to alert the operator of a potential issue. - Equipment Alarms

These alarms focus on the health of specific equipment within the SCADA-controlled environment. Equipment alarms signal mechanical, electrical, or software failures related to pumps, motors, sensors, or other devices. For example, if a motor’s temperature exceeds safe operating limits, an equipment alarm will trigger to warn the operator about a possible malfunction. - Communication Alarms

Communication alarms arise when there is a loss of communication between different components of the SCADA system. This could be due to network issues, broken links, or corrupted data transmissions. Communication alarms are crucial because any failure in communication can disrupt the entire SCADA system, leading to potential safety or operational risks. - Status Alarms

Status alarms provide information about the state of a device or system. For example, a status alarm may indicate whether a valve is open or closed, or if a pump is running or idle. These alarms are typically used for monitoring the operational state of equipment rather than its performance. - Event Alarms

Event alarms are triggered by specific events or changes within the system, such as a system startup, shutdown, or a scheduled maintenance procedure. These alarms may not indicate any immediate issue but serve as a log for recording significant system events that may need follow-up action.

What Are the Levels of SCADA Alarms?

In addition to the different types of SCADA alarms, alarms are also categorized by their severity levels. This categorization helps operators quickly assess the urgency of an alarm and prioritize their response accordingly. The typical levels of SCADA alarms are:

- Critical Alarms

Critical alarms represent the most severe issues and require immediate attention. These alarms are often associated with safety risks or system failures that could lead to significant downtime, equipment damage, or danger to personnel. For instance, if a SCADA system detects a major fault in a safety-critical system, a critical alarm will be raised to alert operators that urgent action is needed.

- Warning Alarms

Warning alarms indicate potential issues that, while not immediately catastrophic, could escalate into more serious problems if left unchecked. These alarms typically give operators time to plan and execute corrective actions, preventing minor issues from developing into major failures.

- Informational Alarms

Informational alarms are the least severe and are used for notifying operators of non-critical system status updates. These alarms provide useful data for monitoring and record-keeping but do not require immediate intervention. Examples include routine status updates or log entries for equipment maintenance.

What Are the Three Main Types of Alarms?

While there are various types of SCADA alarms, they can generally be grouped into three main categories:

- Hard Alarms

Hard alarms are alarms that are directly triggered by system conditions that are out of bounds or otherwise abnormal. These alarms are often critical and demand immediate attention. For example, if a system component exceeds a safe temperature threshold, a hard alarm would be triggered.

- Soft Alarms

Soft alarms are less urgent and typically involve conditions that do not pose an immediate threat to system performance or safety. Soft alarms serve as a warning that conditions are approaching critical thresholds. These alarms help operators anticipate potential issues before they escalate.

- Hysteresis Alarms

Hysteresis alarms are used to monitor systems where minor fluctuations in values are common, but the system should still operate within a defined range. These alarms prevent excessive triggering from small, transient changes. For example, if a temperature fluctuates slightly around a set point, a hysteresis alarm ensures that the system doesn’t continuously trigger alarms for small deviations.

What Are the Different Types of SCADA Alarms PDF?

For those seeking a more detailed reference on SCADA alarms, many organizations and system vendors provide downloadable PDF guides or manuals that explain the various types of alarms in SCADA systems. These resources can serve as helpful documentation for both new and experienced operators to better understand alarm configurations, alarm levels, and troubleshooting procedures.

Conclusion

SCADA alarms are a crucial part of any industrial control system, ensuring the safe and efficient operation of processes. By understanding the different types of SCADA alarms—such as process alarms, equipment alarms, and communication alarms—operators can better respond to potential issues. Additionally, by recognizing the various severity levels of alarms, they can prioritize responses to minimize risks and prevent costly failures.

For more information or a detailed guide on setting up SCADA alarm systems, contact us today!

You might also like