What is IIoT? Industrial Internet of Things

IIoT is the acronym for Industrial Internet of Things, which is the use of the Internet of Things with the aim of improving the efficiency of industrial and manufacturing processes. And, although it is common to use IIoT and Industry 4.0 as synonyms, both concepts present differences.

The Origin of The Industrial Internet of Things (IIoT)

Like its older brother “Internet of Things” ( IoT ) the “Industrial Internet of Things” ( IIoT ) covers a wide range of cases, industries, and applications. Its staging began focused on the search for Operational Excellence and has evolved towards more ambitious and much more transversal objectives. All this “new wave” has been framed under the new concept of Digital Industry Transformation.

The IIoT includes machinery that is connected to the internet and advanced analytics platforms which process the data that is produced. IIoT devices range from environmental sensors to complex industrial robots. While the word “industrial” can refer to warehouses, shipyards, and factories, IIoT technologies hold great promise for a wide range of industry sectors, including agriculture, healthcare, financial services, retail, and advertising.

Basic Composition of an IIoT

The basic composition of an IIoT the system would be, as explained in IoT Agenda, it would be the following:

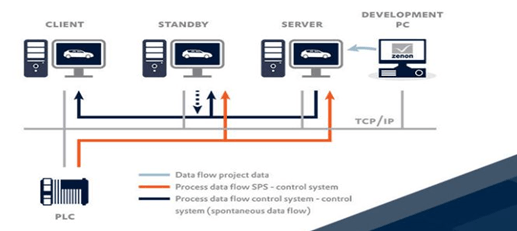

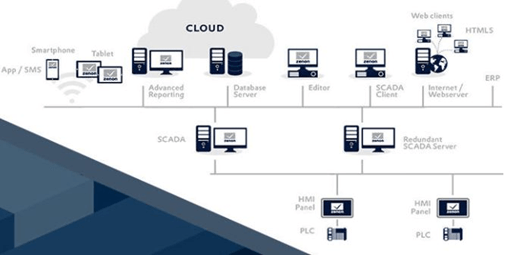

Intelligent devices (sensors, actuators, controllers, etc.) that, in a the schematic arrangement would be located at the base and would have the mission of sensing different parameters, storing information, and communicating it. Gateway (gateway), which would be a higher step and make the interconnection between the above sensors and higher levels through different communication protocols and architectures possible.

These devices increasingly present greater analytical capacity, allowing to carry out first filtering of the information received. This operation shortens response times and reduces the final volume of data to be analyzed. IIoT platform / local server, which is the piece of software that connects everything in an IIoT system and which often constitutes the user’s access point. Infrastructure for data processing (The Cloud), which would be the top of the scheme and the area in which the most complex data analysis would be carried out.

With these new tools, the challenge is to reformulate the management of industrial processes. At the same time, it opens the door to new business models in areas such as after-sales technical service, energy management, maintenance, production optimization, etc. It is at this point when we can talk about Industrial Transformation in all its breadth. This challenge of reformulating everything is not easy. The IIoT tools applied to the industry have allowed the limit to be no longer technology, but people’s imagination and creativity.

You might also like