What is Industry 4.0 with Example?

What is Industry 4.0 with Example?

Advantages and disadvantages of fourth industrial revolution pdf. Industry 4. 0, also referred to as the Fourth Industrial Revolution, is a groundbreaking concept that encompasses the integration of advanced technologies into industrial processes. This integration aims to create a highly connected and automated system that revolutionizes traditional manufacturing and production methods. With Industry 4. 0, industries can leverage cutting-edge technologies such as artificial intelligence, internet of things (IoT), big data analytics, and robotics to drive efficiency, productivity, and innovation in their operations. By seamlessly connecting machines, devices, and systems through the power of digitalization, Industry 4. 0 enables real-time data exchange and intelligent decision-making capabilities that optimize processes, reduce costs, minimize errors, enhance flexibility, and ultimately transform the way goods are manufactured and services are delivered across various sectors. This revolution encompasses technologies such as artificial intelligence, robotics, Internet of Things (IoT), cloud computing, and big data analytics.

Example of Industry 4.0

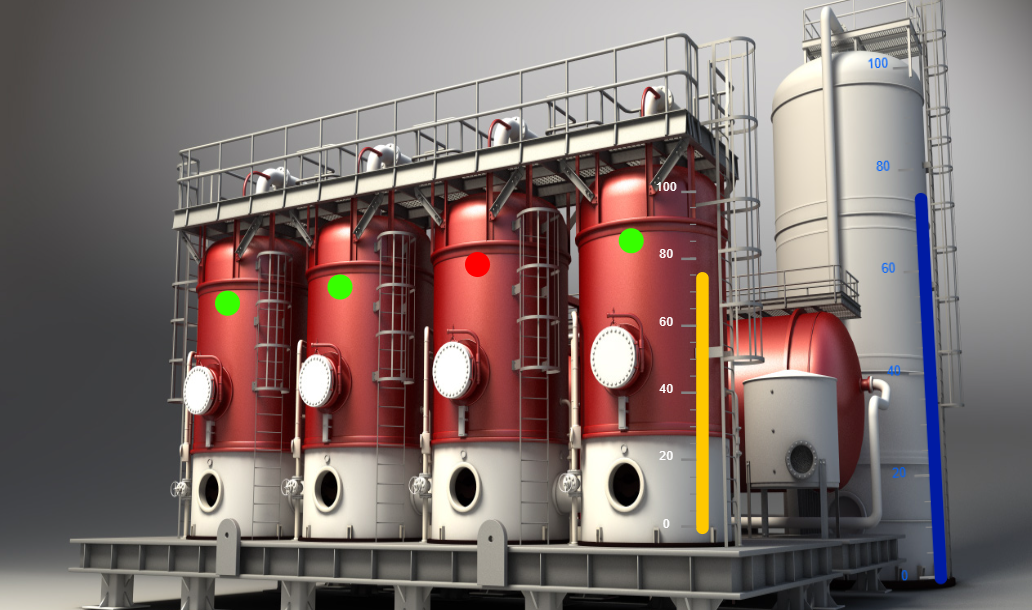

One concrete example of the revolutionary Industry 4. 0 concept is the implementation of smart factories. These cutting-edge manufacturing facilities are characterized by the integration of advanced technologies, where machines and equipment are interconnected and communicate seamlessly with each other through Internet of Things (IoT) sensors. This interconnectedness enables real-time data sharing and analysis, enhancing operational efficiency, productivity, and overall performance within the factory environment. By enabling machines to communicate and collaborate effectively, smart factories pave the way for increased automation, predictive maintenance, optimized inventory management, and improved quality control processes. Consequently, this transformation in manufacturing enhances production capabilities while reducing costs and minimizing downtime for businesses embracing this transformative paradigm shift in industrial operations. This enables real-time monitoring and control of production processes, leading to increased efficiency and productivity.

Advantages of Industry 4.0

Industry 4. 0, the fourth industrial revolution, brings with it a multitude of advantages that have the potential to transform businesses and industries. One of the key benefits is the significant improvement in productivity that it offers. By leveraging advanced technologies such as artificial intelligence, robotics, and Internet of Things (IoT), companies can automate repetitive tasks and streamline processes, resulting in increased efficiency and output. In addition to improved productivity, Industry 4. 0 also enables cost reduction through automation. By implementing intelligent systems and machines, businesses can minimize manual labor requirements and optimize resource allocation. This not only leads to lower operational costs but also eliminates human errors, resulting in enhanced accuracy and consistency. Quality control is another area where Industry 4. 0 excels. With advanced sensors and data analytics capabilities, real-time monitoring of production processes becomes possible. This allows for proactive identification of potential issues or deviations from desired standards, enabling prompt corrective actions to be taken. As a result, product quality is significantly enhanced while minimizing waste or defective items. Furthermore, Industry 4. 0 facilitates faster decision-making by providing access to real-time data analysis. Through interconnected devices and smart systems, businesses can gather vast amounts of data from various sources across their operations. This data can be processed and analyzed instantaneously using advanced algorithms, enabling timely insights into performance metrics, market trends, customer preferences, and more. By harnessing the advantages offered by Industry 4. 0 technologies such as improved productivity, reduced costs through automation, enhanced quality control measures, and faster decision-making based on real-time data analysis; businesses can gain a competitive edge in today's rapidly evolving digital landscape while driving innovation and growth. It also opens up new business models and opportunities for innovation.

Disadvantages of Industry 4.0

Nevertheless, it is crucial to consider the potential drawbacks that come with the usage of AI writing assistants. While they are highly efficient and can produce content quickly, there may be instances where their output lacks the human touch or creativity. Additionally, relying solely on AI writing assistants may hinder the development of essential writing skills among professionals. It is important to strike a balance between utilizing these tools for efficiency and ensuring that human expertise and creativity are not compromised in the process. These include concerns about job displacement due to automation, cybersecurity risks associated with interconnected systems, the need for significant investments in technology infrastructure and training programs for employees.

5th Industrial Revolution

It is important to mention that as of now, there is no distinct term known as "Industry 5. 0." However, it is widely acknowledged and recognized as an extension or evolution of the concept of Industry 4. 0. This progression signifies the continuing advancement and integration of technologies such as artificial intelligence, automation, Internet of Things (IoT), and data analytics within industrial processes. The term "Industry 5. 0" emphasizes the collaborative interaction between humans and machines to enhance productivity and create a more efficient and sustainable industrial landscape.

Importance of the Fourth Industrial Revolution

The Fourth Industrial Revolution holds immense significance due to its potential to revolutionize industries across a multitude of sectors. By harnessing cutting-edge technologies, it aims to enhance efficiency, foster competitiveness, and promote sustainability. This transformative era is set to redefine the way businesses operate by incorporating advancements such as artificial intelligence, robotics, Internet of Things (IoT), and data analytics. These technologies enable companies to streamline processes, optimize resource utilization, and make informed decisions based on real-time data for improved productivity and profitability. Moreover, the Fourth Industrial Revolution also presents an opportunity for businesses to embrace sustainable practices by reducing their carbon footprint and adopting eco-friendly solutions. By embracing this paradigm shift, industries can unlock new growth opportunities while contributing towards a more sustainable future for generations to come.

Industry 4.0 Companies

In the ever-evolving landscape of technology, an increasing number of companies have wholeheartedly embraced the principles of Industry 4. 0 in their day-to-day operations. This paradigm shift marks a significant departure from traditional manufacturing methods and represents a seamless integration of cutting-edge technologies like artificial intelligence, internet of things (IoT), big data analytics, and automation into industrial processes. By leveraging these advanced tools and techniques, organizations can achieve unprecedented levels of productivity, efficiency, and competitiveness while paving the way for the factories and workplaces of the future. Some notable examples include Siemens with its Digital Factory initiative focusing on automation solutions for manufacturing processes; General Electric's Predix platform that enables predictive maintenance in industrial settings; and Amazon's use of robotics and AI-powered systems in its fulfillment centers.

To learn more about the advantages and disadvantages of the Fourth Industrial Revolution or gain insights into specific examples or case studies related to this topic, you can refer to PDF documents available online or explore PowerPoint presentations that delve deeper into these subjects.

You might also like