What Is Industry 5.0 McKinsey?

What Is Industry 5.0 McKinsey

What Does Industry 4.0 Mean?

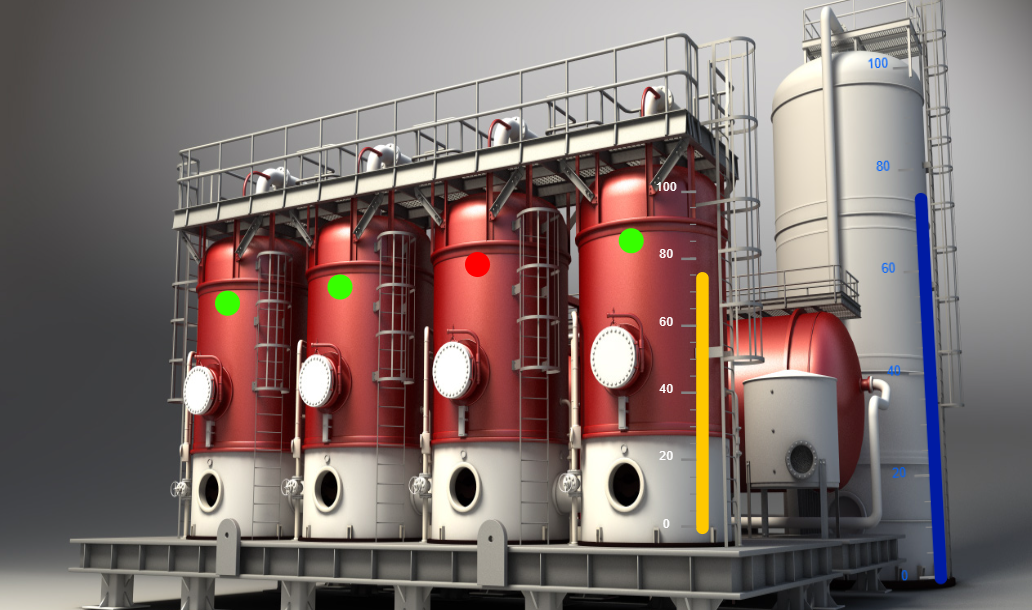

Industry 4.0 books, also known as the Fourth Industrial Revolution, refers to the integration of digital technologies and automation into manufacturing processes. In the realm of technological advancements, the concept of smart factories has emerged, bringing together a plethora of cutting-edge technologies such as artificial intelligence (AI), Internet of Things (IoT), cloud computing, and robotics. This integration aims to revolutionize traditional manufacturing processes by making them more efficient, flexible, and interconnected. By leveraging AI algorithms, smart factories can optimize production lines, automate mundane tasks, and enhance overall operational performance. The IoT enables seamless connectivity between machines and systems, facilitating real-time data exchange and enabling predictive maintenance. Cloud computing empowers these factories with scalable storage and processing capabilities while offering the flexibility to access data remotely. Robotics plays a vital role in automating repetitive tasks and working alongside human operators to improve productivity. Together, these technological advancements have paved the way for smarter factories that can adapt to changing demands swiftly while achieving higher levels of efficiency and productivity.

What Does Industry 4.0 Mean in Supply Chain?

The concept of Industry 4.0 has revolutionized the field of supply chain management, bringing about significant changes and advancements. With the implementation of Industry 4.0 technologies, such as Internet of Things (IoT) devices and advanced data analytics, real-time tracking and monitoring of inventory have become possible. This allows businesses to have a comprehensive view of their stock levels at any given moment, resulting in improved inventory management and more efficient logistical operations. Furthermore, Industry 4.0 enables enhanced demand forecasting through the utilization of data analytics tools. By analyzing historical sales data, market trends, and customer behavior patterns, businesses can accurately predict future demand patterns. This empowers them to optimize their production schedules, minimize stockouts or overstocks, and ultimately improve customer satisfaction. Another crucial aspect that Industry 4.0 brings to the table is enhanced communication between suppliers and customers within the supply chain network. Through interconnected systems and digital platforms, suppliers can seamlessly share real-time information with customers regarding order status updates, shipment tracking details, or any potential disruptions in the supply chain. Such transparent communication fosters trust between all stakeholders involved and leads to better coordination throughout the supply chain. In summary, Industry 4.0 has transformed supply chain management by introducing real-time tracking capabilities for inventory management, leveraging data analytics for accurate demand forecasting, and facilitating seamless communication between suppliers and customers across the entire supply chain network.

Industry 4.0 Benefits

The introduction of Industry 4.0 has brought forth a multitude of benefits that have positively impacted various aspects of businesses. One such advantage is the significant increase in productivity achieved through automation. By leveraging advanced technologies and intelligent systems, companies can streamline their operations, minimize human error, and maximize output efficiency. Another noteworthy benefit lies in the improved product quality that Industry 4.0 enables. With the integration of sophisticated monitoring systems, businesses can closely track production processes and identify potential issues or deviations in real-time. This proactive approach allows for immediate corrective actions to be taken, resulting in higher quality products and enhanced customer satisfaction. Furthermore, Industry 4.0 offers substantial cost reductions by optimizing processes across all stages of production. Through data-driven insights and advanced analytics, companies can identify inefficiencies, eliminate wasteful practices, and make informed decisions on resource allocation. This not only leads to cost savings but also increases overall operational effectiveness. Moreover, Industry 4.0 revolutionizes customer experiences by enabling personalized products or services on a mass scale. With the capability to collect vast amounts of customer data and leverage artificial intelligence algorithms, businesses can tailor their offerings to individual preferences and requirements more effectively than ever before. This level of customization enhances customer satisfaction and loyalty while driving competitive advantage in today's market. In summary, embracing Industry 4.0 brings forth numerous advantages including increased productivity through automation, improved product quality through advanced monitoring systems, reduced costs via process optimization, and enhanced customer experiences through personalized products or services tailored to individual needs.

What Is an Example of the Industry 4.0 Revolution?

An exemplary illustration of the profound revolution brought about by Industry 4.0 is the remarkable implementation of smart factories. These cutting-edge manufacturing environments seamlessly integrate advanced technologies, allowing machines to communicate with one another in real-time. This revolutionary level of interconnectivity enables the optimization of production processes without the need for human intervention. By harnessing the power of Artificial Intelligence and Internet of Things (IoT), smart factories redefine efficiency, accuracy, and productivity in industrial settings.

If you are looking for more information about Industry 4.0, there are various books available on the subject that delve into its concepts and implications for different industries.

While there is no specific term called "Industry 5.0," it is possible that it refers to a hypothetical future stage beyond Industry 4.0 where even more advanced technologies will be integrated into industrial processes for further optimization and efficiency gains.

If you are searching for a PDF on Industry 4.0 specifically or any related topic within this field, it is recommended to explore reputable online platforms or academic databases where you can find scholarly articles or research papers in PDF format that provide valuable insights into this subject matter.

You might also like