The OPC protocol, undoubtedly, plays a pivotal role in the industrial automation environment. It establishes a solid foundation by providing a standardized and efficient method for devices and applications to seamlessly exchange data. By ensuring interoperability between diverse vendors' hardware and software systems, it eliminates the hassle of integration and simplifies the process of constructing a unified SCADA system. With OPC at the forefront, businesses can effortlessly integrate various components into their automation infrastructure with confidence and ease.

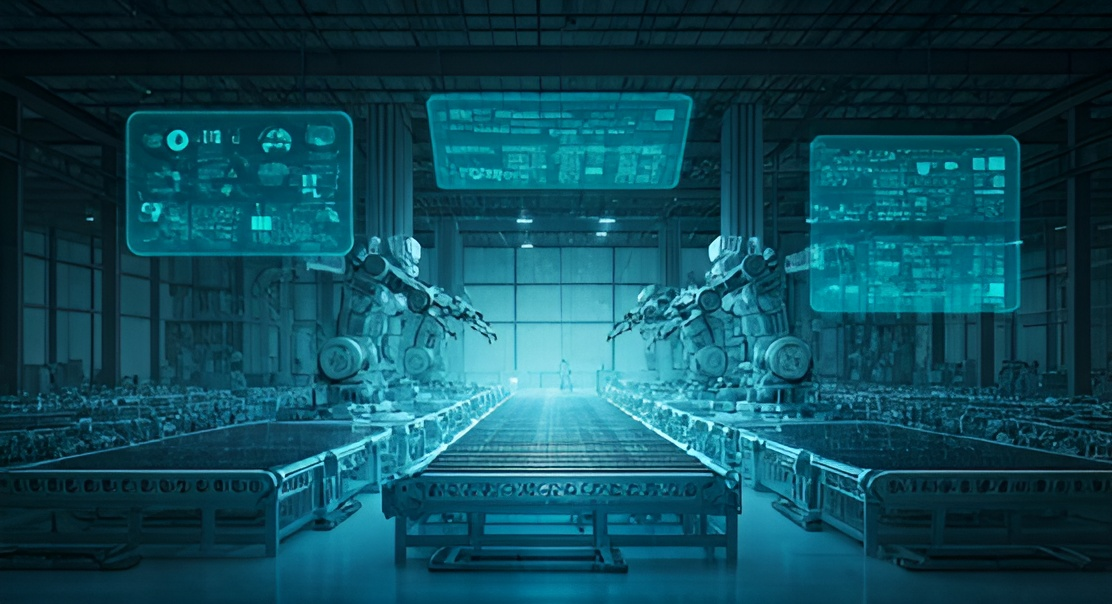

Let's take a concrete example to illustrate the power of an OPC server. Imagine a manufacturing plant with multiple sensors monitoring temperature in real-time. With the help of an OPC server, this valuable data can be effortlessly collected from all these sensors and flawlessly transmitted to the SCADA server. This seamless integration ensures that crucial temperature readings are received promptly and accurately, allowing for swift decision-making and optimal control of the manufacturing processes. The highly sophisticated SCADA system excels in its ability to thoroughly analyze the vast amount of information it receives from the OPC server. Its primary function is to tirelessly monitor process variables, detect even the slightest anomalies, promptly trigger alarms when necessary, and make well-informed decisions based on meticulous analysis of historical trends. The SCADA system's unparalleled capabilities empower organizations to proactively address potential issues and optimize operational efficiency with utmost precision and accuracy.