What is SCADA?/Where to Buy Best SCADA System?

What is SCADA?/Where to Buy Best SCADA System?

SCADA systems are critical to a wide range of industrial organizations. These systems allow organizations to control assets of various sizes, as well as entire factories. With SCADA-based live data management system, you can easily obtain information about operations, control your processes and make a data-driven business decision.

Definition of SCADA

In full, SCADA means supervision and data acquisition, a term that describes the basic functions of a SCADA system. Companies can use SCADA systems to control equipment in different locations and to collect and save data about their operations.

SCADA is typically a combination of software and hardware elements, such as programmable logic controllers (PLCs) and remote terminal units (RTUs). Data acquisition starts with PLCs and RTUs, which communicate with shop equipment, such as machines and sensors. The data collected from the equipment is sent to the next level, such as the control room, where operators can supervise PLC and RTU controls using HMI SCADA. The HMI’s is an important element of SCADA systems. They are the screens used by operators to communicate with the SCADA system.

By using SCADA systems, organizations can control their industrial processes locally or remotely and interact directly with individual equipment, such as motors, pumps, and sensors across the line from a central location. In some cases, these systems can automatically control equipment based on the data received. SCADA systems also allow organizations to monitor and report on their processes based on real-time data and archive the data for further processing and evaluation.

How Does SCADA Software Work?

The data from field machines (shop floor) is firstly transported to the controllers (PLCs and RTUs). This equipment is supervised by Human-Machine Interfaces (HMI such interfaces contain the visual structure of the SCADA system, in which employees can access all data and apply the necessary actions, even remotely. In HMIs it is possible to identify alarms and also the operating conditions. Generally, SCADA software has a visual structure that is easy for all users to understand. The operator can create customized controls and screens, configure their appearance and the variables that will be useful to them, that is, the level, pressure, flow, temperature, etc. measurements. They will be inserted as topics or tags. After that, an interaction can be made with all the equipment in the factory. Some of the functions of this system can be performed automatically, according to the received data and configuration.

SCADA Applications

Organizations can use SCADA systems to:

- Control processes locally or remotely

- Interact with devices through the software’s HMI

- Collect, monitor, and process data

- Record events and data

Such functions provide companies with greater visibility of their processes. The collected data allows us to analyze the operation of the machines in real-time and also to visualize long-term trends to identify opportunities for improvement. Based on this data, operators can then make adjustments to the equipment using the controls enabled by SCADA. They can make changes locally or remotely and can adjust operations at the level of complete installations, individual processes, or just on certain machines in particular.

SCADA systems also allow organizations to use their data to improve efficiency, make informed decisions and improve communication to help prevent downtime. Well-integrated SCADA software can combine data from different sources, process it, and send it to other systems in different formats.

Advanced SCADA software can create complete, customized reports. Your equipment may also be able to automatically react to the information in those reports. In a quality management application, for example, the system can activate an alarm if a report indicates that a batch of the product is defective. In energy management, a system can reduce the energy consumption of a particular machine or system in the event of a peak load forecast.

Through functions like these, SCADA systems can help companies make considerable savings in terms of time and money. They can help companies increase the efficiency of their operations, reduce downtime, ensure product quality, and more.

SCADA systems can range from relatively simple to complex and large-scale systems, depending on the organization that uses them and the applications in which they are used.

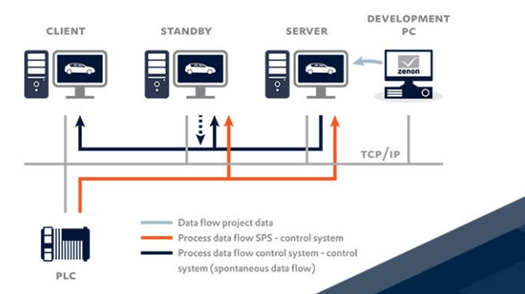

A Basic SCADA Network

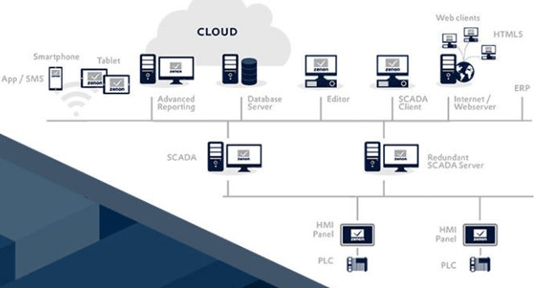

A Comprehensive SCADA Network

SCADA systems are important for large and small organizations in several types of sectors, including:

- Energy and Infrastructure

- Food and Drinks

- Pharmaceutical

- Automotive

- Water and Sewage

- Transport

- Buildings

- Inter-Sectoral Applications

For most sectors and organizations, SCADA systems play a vital role in how companies control their operations and how they use their operational data to make the best decisions.

Where to Buy Best SCADA System?

Empowered Automation Solutions Inc., based in Chicago, Illinois, allows you to automate things as per your needs with the Best SCADA System.

You might also like