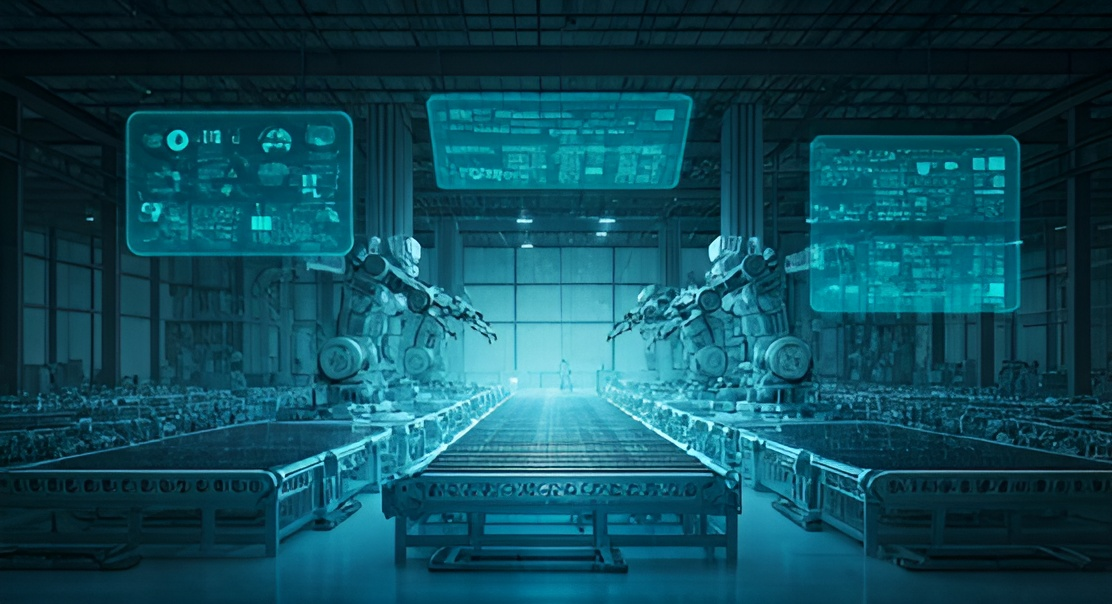

History of MES – Manufacturing Execution System

Competition has grown exponentially in recent decades, leading companies to take several measures to increase productivity and reduce costs. This combination has been implemented in various ways, ranging from the transfer of production units to countries with low labor costs to the use of industrial management software and other computerized tools to plan, control, and increase the productive performance of human resources and materials. In this article empowered automation will tell you the History of MES.

The use of computerized systems to support productive activities began with the emergence of large computers, the mainframes, created in the 40s, which were only incorporated in conventional companies in the 50s and 60s. Initially linked to the finance department, especially to the accounting, were then applied to other areas of the companies, namely production, initially in cost and inventory analysis, then in planning and control.

Industry support has evolved and led to the emergence of various types of systems, such as Material Requirements Planning – MRP (Material Needs Planning), in the 60s, which converts a production plan into a list of quantities of materials needed for its execution, Manufacturing Resources Planning – MRP II (Production Resources Planning), in the ’80s, which broadens the range of analysis of the previous tool, incorporating the needs of human resources, equipment, energy, financial resources. In this period, these solutions were generically treated as CIM, from English Computer Integrated Manufacturing.

As an evolution of the MRP II concept, the Enterprise Resource Planning integrated solutions emerge, which turn out to be an eminently administrative-financial tool, providing little support to production, especially through the logistics and production.

History of MES – Manufacturing Execution System Came About

One of the most recent elements of this set is the MES – Manufacturing Execution System, which enables real-time planning, control, and monitoring of the various production processes and stages, both in terms of physical quantities of raw materials, intermediate and finished products, as well as in terms of financial costs of any nature – personnel, energy, raw materials, intermediate products, etc. An MES performs all the functions of MRP and MRP II, that is, the MES bridges production planning and control by obtaining it online, directly from equipment such as scales, bar code readers, and others, or manually, but always in real-time, of production variables.

The name MES was created by the company AMR Research in 1990 and 1992 a group of software development, consultants, and solution integrators created the Manufacturing Execution Systems Association – MESA, (currently Manufacturing Enterprise Solutions Association), which defined a set of eleven functionalities that would be mandatory for any application that purported to obtain this classification and which is known as the MESA model.

In 2000, the International Society of Automation elaborated the first part of the ANSI-ISA-95 standard and three more until the year 2010. This standard establishes a standard for terminology, activities, and functions, as well as the hierarchy of these functions, standardization between interfaces of an MES system.

Additional Benefits

- Accelerate trace analysis, root cause diagnosis, and problem resolution

- Lower cost for good quality

- Continuously improve product quality and new projects

- Make operational and strategic decisions based on facts

- Complete control over your manufacturing process