Is SCADA Outdated?

Is SCADA Outdated

The question of is SCADA outdated arises frequently as industries increasingly adopt new technologies. While some argue that traditional systems lack the flexibility needed for modern applications, advancements in integration have kept SCADA relevant. The evolving SCADA System continues to support real-time monitoring and data analysis, adapting to meet contemporary demands. Ultimately, with the right updates, SCADA can coexist with emerging technologies rather than becoming obsolete.

SCADA IoT Architecture

SCADA IoT architecture integrates traditional supervisory control and data acquisition systems with Internet of Things technologies, revolutionizing industrial automation. This architecture enables seamless connectivity between devices, allowing for real-time data collection and analysis. By leveraging cloud computing and advanced analytics, organizations can gain deeper insights into their operations, enhancing decision-making and responsiveness. Ultimately, SCADA IoT architecture empowers industries to optimize processes and improve efficiency in an increasingly connected world.

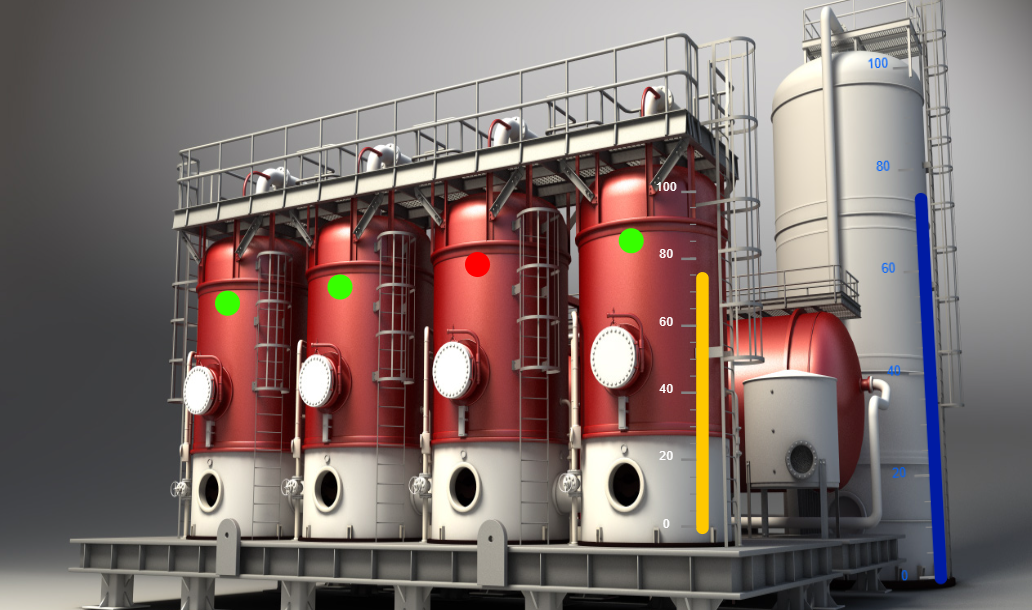

SCADA System

A SCADA system is a crucial framework used for monitoring and controlling industrial processes across various sectors. It facilitates real-time data acquisition, allowing operators to track equipment performance, manage resources, and respond swiftly to any anomalies. By providing centralized control and visualization, SCADA systems enhance operational efficiency and safety. As industries evolve, modern SCADA systems increasingly incorporate advanced technologies, ensuring they remain vital for effective automation and management.

What is the Alternative to SCADA

Alternatives to SCADA systems include Distributed Control Systems (DCS) and Industrial Internet of Things (IIoT) platforms. DCS is often preferred for complex processes that require extensive control and integration across multiple components. IIoT platforms leverage cloud computing and big data analytics, allowing for real-time data processing and enhanced decision-making capabilities. These alternatives can provide greater flexibility and scalability, catering to the evolving needs of modern industrial environments.

What Will Replace SCADA Reddit

On Reddit, discussions about what might replace SCADA often highlight the rise of IoT solutions and cloud-based platforms. Many users suggest that IIoT systems, with their ability to connect numerous devices and analyze vast amounts of data, offer superior flexibility and efficiency. Others point to the integration of AI and machine learning technologies as key advancements that can enhance predictive maintenance and process optimization. Overall, the sentiment suggests that while SCADA remains valuable, its future will likely involve significant integration with newer technologies.

Difference Between IoT and SCADA

The primary difference between IoT and SCADA lies in their architecture and functionality. SCADA systems are designed for centralized monitoring and control of industrial processes, while IoT encompasses a broader network of interconnected devices that collect and share data in real-time. IoT solutions typically leverage cloud computing, enabling more scalable data analysis and integration across various applications. In contrast, SCADA is often more focused on specific operational processes, making IoT a more flexible option for diverse use cases beyond traditional industrial automation.

What is Better Than SCADA

When considering what is better than SCADA, alternatives like Distributed Control Systems (DCS) and IoT platforms often come to mind. DCS is particularly effective for complex industrial processes, providing more flexibility and integration capabilities. Meanwhile, IoT platforms leverage cloud computing and big data analytics, offering real-time insights and advanced data processing beyond traditional SCADA systems. Ultimately, the choice depends on the specific needs of an organization, as each option brings unique advantages to the table.

What is Better Than SCADA IoT

When considering what is better than SCADA IoT, cloud-based industrial IoT platforms often come to the forefront. These platforms offer enhanced scalability, flexibility, and advanced analytics capabilities, allowing organizations to process vast amounts of data in real time. Additionally, artificial intelligence (AI) integration can further optimize operations by enabling predictive maintenance and automated decision-making. Ultimately, while SCADA IoT provides valuable insights, these alternatives can deliver even greater efficiency and innovation in industrial automation.

What is the Future of SCADA

The future of SCADA is set to be shaped by advancements in technologies like IoT, artificial intelligence, and machine learning. As industries move toward greater automation and digitalization, SCADA systems will evolve to offer enhanced real-time monitoring, predictive analytics, and improved data security. Integration with cloud computing will provide greater flexibility, enabling remote access and scalability for businesses of all sizes. Ultimately, SCADA will play a crucial role in driving efficiency and innovation across various sectors.

What is the Future of SCADA Systems 2021

In 2021, the future of SCADA systems was marked by a significant shift toward cloud-based solutions and increased connectivity with IoT devices. This transition enabled more agile operations, allowing organizations to gather and analyze data in real-time from remote locations. The focus on cybersecurity also intensified, as protecting sensitive data became paramount amidst growing threats. Overall, SCADA systems in 2021 laid the groundwork for smarter, more resilient industrial processes.

What is SCADA System and Its Application

A SCADA system (Supervisory Control and Data Acquisition) is a software-based solution used to monitor and control industrial processes in real time. It collects data from sensors and devices in the field, allowing operators to visualize and manage operations efficiently. SCADA systems are widely used in various applications, including manufacturing, energy management, water treatment, and transportation. Their ability to provide real-time insights and automated control makes them essential for enhancing operational efficiency and ensuring safety in critical infrastructure.

Is SCADA Obsolete

The question of whether SCADA is obsolete arises as new technologies emerge and industries evolve. While some argue that traditional SCADA systems lack the flexibility needed for modern applications, many systems are being upgraded to incorporate IoT and cloud capabilities. These enhancements allow SCADA to remain relevant by providing real-time data analysis and improved decision-making tools. Ultimately, with the right upgrades and integrations, SCADA can coexist with new technologies rather than becoming obsolete.

SCADA Software

SCADA software serves as the backbone of industrial automation, enabling users to monitor and control processes in real time. This software collects data from sensors and devices, presenting it in user-friendly interfaces for efficient analysis and decision-making. Modern SCADA solutions often include features such as remote access, advanced analytics, and integration with IoT devices, enhancing their functionality. As industries increasingly demand more sophisticated solutions, SCADA software continues to evolve, incorporating innovative technologies to meet these needs.

SCADA System PDF

A SCADA system PDF typically provides comprehensive documentation about the architecture, functionality, and applications of SCADA systems. These documents serve as valuable resources for understanding how SCADA integrates into industrial processes and can outline best practices for implementation and maintenance. They may also include case studies, technical specifications, and troubleshooting tips, making them essential for engineers and operators. By providing detailed insights, SCADA system PDFs help organizations leverage these systems effectively for optimal performance.

Will IoT Replace SCADA?

The question of whether IoT will replace SCADA is complex, as both technologies serve distinct but complementary roles in industrial automation. While IoT offers enhanced connectivity and data analytics capabilities, SCADA systems remain essential for real-time monitoring and control of processes. Rather than a complete replacement, the future likely involves the integration of IoT with SCADA to create more robust and efficient systems. This hybrid approach allows organizations to leverage the strengths of both technologies for improved

SCADA Full Form

The full form of SCADA is Supervisory Control and Data Acquisition. This term describes a system used for monitoring and controlling industrial processes, such as manufacturing, energy distribution, and water treatment. SCADA systems gather real-time data from remote locations and facilitate centralized control, enabling operators to make informed decisions. Understanding this full form highlights the system's core functions of supervision, control, and data management in various industries.

SCADA and IoT Difference

The primary difference between SCADA and IoT lies in their focus and application. SCADA is a system specifically designed for monitoring and controlling industrial processes, providing real-time data and centralized control. In contrast, IoT encompasses a broader range of interconnected devices and sensors that communicate over the internet, enabling data collection and analysis across diverse applications. While SCADA typically operates within defined parameters, IoT offers greater flexibility and scalability, allowing for innovative solutions in areas beyond traditional industrial automation.

What is the Future of SCADA Systems

The future of SCADA systems is expected to be shaped by the integration of advanced technologies like IoT, AI, and big data analytics. These innovations will enhance real-time data processing, enabling smarter decision-making and predictive maintenance. Additionally, the shift toward cloud-based architectures will improve scalability and accessibility, allowing for remote monitoring and control. As industries focus on automation and efficiency, SCADA systems will increasingly adapt to support a more interconnected and responsive operational landscape.

What Will Replace SCADA: Reddit IoT

On platforms like Reddit, discussions about what might replace SCADA often highlight the rise of IoT platforms that offer more flexibility and functionality. These IoT solutions can provide real-time analytics, machine learning capabilities, and greater interoperability between devices, making them appealing alternatives. Additionally, users emphasize the potential of edge computing, which allows for data processing closer to the source, reducing latency and improving response times. While traditional SCADA systems will continue to play a role, the community's sentiment suggests a gradual shift toward these more modern, integrated technologies for future industrial automation.

What Will Replace SCADA

The future landscape of industrial automation may see various technologies gradually replacing traditional SCADA systems. Innovations such as cloud-based IoT platforms and advanced data analytics are emerging as powerful alternatives, offering real-time insights and scalability. Additionally, the integration of artificial intelligence can enhance predictive maintenance and decision-making capabilities, allowing organizations to optimize their operations. As these technologies continue to evolve, they promise to deliver more flexibility and efficiency than traditional SCADA solutions.

What is Better Than SCADA Reddit

On platforms like Reddit, discussions about alternatives to SCADA often highlight options like Distributed Control Systems (DCS) and IoT platforms as superior choices. Users emphasize that DCS provides better integration for complex processes, while IoT solutions offer real-time data access and cloud capabilities. Many also mention the benefits of AI-driven systems for predictive analytics, allowing for proactive maintenance and operational improvements. Ultimately, the community's consensus suggests that the best solution depends on specific industry needs and operational requirements.

Ignition SCADA

Ignition SCADA is a powerful, web-based industrial automation platform designed for real-time monitoring and control of processes. It offers extensive flexibility with features like drag-and-drop visualization, robust data handling, and seamless integration with IoT devices. With a focus on open architecture, Ignition allows users to customize and scale their systems according to specific operational needs. Its ability to provide centralized access and manage data from multiple sources makes it an attractive choice for modern industrial applications.

IoT vs PLC SCADA

The comparison of IoT vs PLC SCADA highlights two distinct approaches to industrial automation. IoT systems focus on connectivity and data exchange across a network, leveraging cloud computing and advanced analytics for real-time insights. In contrast, PLC SCADA systems traditionally manage localized control processes, often requiring physical connections to sensors and actuators. While IoT provides enhanced scalability and flexibility, PLC SCADA remains crucial for reliability and deterministic control in mission-critical applications.

What is the Alternative to SCADA Reddit

On platforms like Reddit, discussions about what is the alternative to SCADA often explore modern solutions like cloud-based IoT platforms and DCS (Distributed Control Systems). Users highlight the benefits of these alternatives, including improved scalability, advanced data analytics, and integration with machine learning technologies. Many contributors emphasize the importance of selecting a solution based on specific operational needs and industry requirements. Overall, the conversation reflects a growing trend toward embracing innovative technologies that enhance automation and efficiency.

You might also like