MES System Integration

What is MES PLC Integration?

MES (Manufacturing Execution System) and PLC (Programmable Logic Controller) integration is the marriage of two crucial manufacturing systems. MES acts as the brain of the shop floor, managing production in real-time and tracking everything from materials to quality control. PLCs are the brains of individual machines, controlling their operations and responding to sensor data. By connecting these two systems, manufacturers can unlock a wealth of benefits. MES gets immediate updates on machine performance, production output, and potential issues directly from the PLCs. This real-time data allows for better decision-making, optimized scheduling, and improved efficiency. MES can even send work orders and instructions directly to PLCs, reducing manual tasks and streamlining processes. Overall, MES PLC integration creates a powerful information flow that optimizes production, improves quality control, and drives smarter manufacturing.

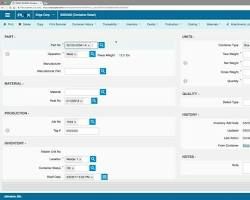

MES Software

A Manufacturing Execution System (MES) is a comprehensive, dynamic software system that monitors, tracks, documents, and controls the process of manufacturing goods from raw materials to finished products. Positioned between enterprise resource planning (ERP) systems and process control, an MES provides decision-makers with real-time data to enhance plant floor efficiency and optimize production. It plays a crucial role in regulated industries like pharmaceuticals, food and beverage, medical devices, aeronautics, aerospace, and biotechnology, ensuring compliance with strict traceability regulations. MES software contributes to overall productivity and profitability by making manufacturing processes information-driven, and it’s projected to generate substantial revenue globally by 2025

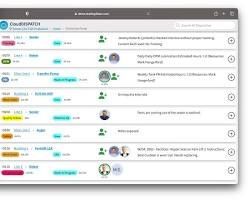

What is the Integration Between MES and ERP

Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) are crucial components in manufacturing. MES systems operate on the shop floor, tracking real-time production processes, while ERP handles administrative and operational aspects. Integrating them offers benefits like streamlined operations, real-time data synchronization, and enhanced efficiency. Successful integration involves defining objectives, selecting tools, data mapping, testing, and change management. Challenges include data consistency and legacy systems. Advanced Planning and Scheduling (APS) tools play a vital role in efficient scheduling and resource allocation. Overall, MES-ERP integration unifies production and administration, driving success in manufacturing.

MES vs ERP

MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning) software serve different purposes in manufacturing. Here's a quick breakdown of the key differences:

- Focus: MES concentrates on the shop floor, optimizing production processes and operations in real-time. ERP takes a broader view, managing resources and information across the entire business, including finance, HR, and sales.

- Data: MES gathers real-time data on equipment, materials, and worker activity. ERP deals with more static data like inventory levels, customer orders, and financial records.

- Impact: MES directly impacts product quality through production control. ERP indirectly affects quality by improving resource planning and analysis.

While separate, MES and ERP can work together. MES feeds data to ERP, providing a more complete picture of manufacturing operations. This improves overall efficiency and decision-making across the business.

What is MES Integration Job Description

An MES Integration job bridges the gap between Manufacturing Execution Systems (MES) and other factory floor systems. You'll essentially be a translator, ensuring seamless communication between the MES, which manages overall production, and other systems like PLCs (controlling machines) or enterprise software (ERP). The role involves analyzing data requirements, designing integrations, and configuring the MES to work flawlessly with existing systems. You might also write scripts or code to automate data flow and troubleshoot any integration issues. This role requires a blend of technical skills (understanding MES, data protocols) and business knowledge (production processes) to ensure the MES effectively optimizes and monitors the entire manufacturing operation.

Manufacturing Execution System Software List

There are many Manufacturing Execution System (MES) software options available, catering to different industry needs and company sizes. Here are a few:

Plex Systems: Offers a comprehensive MES solution for discrete manufacturing, including production planning, scheduling, execution, and quality control.

SAP Digital Manufacturing Cloud: Provides a cloud-based MES solution that integrates with SAP ERP systems for seamless data flow and improved operational visibility.

Tulip: A cloud-based MES platform designed for ease of use and scalability. Tulip offers a visual drag-and-drop interface for building custom applications to manage production processes.

Epicor Advanced MES: A comprehensive MES solution for complex manufacturing environments. Epicor offers strong functionality in areas like production planning, scheduling, quality control, and traceability.

L2L Smarter Manufacturing: An on-premise MES solution that is well-suited for lean manufacturing operations. L2L offers features like Kanban boards, takt time calculations, and continuous improvement tools.

MasterControl Manufacturing Excellence: An MES solution designed to meet the needs of regulated industries such as medical device and pharmaceutical manufacturing. MasterControl offers strong compliance management capabilities.

Is SAP an MES System?

SAP Manufacturing Execution System (SAP MES) is a powerful solution for managing manufacturing operations. Positioned between Enterprise Resource Planning (ERP) and process control systems, it monitors, tracks, and controls production processes. MES benefits include improved quality control, increased uptime, reduced inventory, and a paperless shop floor. It’s particularly valuable in regulated industries due to strict traceability requirements. Overall, SAP MES enhances reliability, traceability, and efficiency in manufacturing environments.

MES Software Vendors

Here are some Manufacturing Execution System (MES) software vendors that offer robust solutions for managing and optimizing production processes:

- Siemens Opcenter Execution: Siemens Opcenter is a standard MES system known for its flexibility and comprehensive manufacturing functionalities. It provides an easy-to-use interface for production operations and factory management.

- Plex Smart Manufacturing Platform: Plex offers an integrated solution that covers various departments, including finance, HR, sales, production, quality, and more. It brings efficiency to daily work by providing real-time data and streamlining processes

- Proficy Smart Factory MES by GE Digital: GE Digital’s MES product offers highly visualized management and monitoring capabilities. It enhances production scheduling, material tracking, and quality management. The sleek and intuitive user interface ensures a great working experience for production teams

How do you Implement a MES System?

Implementing a Manufacturing Execution System (MES) involves several key steps to ensure success. Here’s a concise summary:

- Planning and Preparation:

- Assess Your Needs: Understand your organization’s requirements and objectives. Identify pain points, areas for improvement, and specific goals.

- Stakeholder Involvement: Engage leaders from IT, production, quality, maintenance, and planning. Collaborate to gather requirements and ensure alignment.

- Configuration and Fine-Tuning: Plan for system configuration, connectivity, and data extraction. Define what needs to be connected and how to maximize data utilization.

- Gradual Implementation:

- Agile Approach: Remain flexible and adapt as needed during the implementation process.

- Bridge the Gap: MES acts as a bridge between planning (ERP) and control (PLC) systems. It provides real-time monitoring and control of manufacturing processes.

- Evolve with the Solution: Continuously evolve your MES to unlock its full potential and enhance manufacturing operations

Is SCADA an MES System?

SCADA (Supervisory Control and Data Acquisition) systems focus on real-time monitoring and control of industrial processes, collecting data from sensors and devices. They operate at the supervisory level and are commonly used in utilities, oil and gas, and transportation. On the other hand, MES (Manufacturing Execution Systems) manage production processes, work orders, quality control, and inventory at the shop floor level. MES bridges the gap between enterprise resource planning (ERP) systems and shop floor operations. Examples of MES systems include Siemens Opcenter Execution, Plex Smart Manufacturing Platform, and Proficy Smart Factory MES by GE Digital. These systems play distinct roles in industrial automation, complementing each other to enhance overall efficiency and productivity in manufacturing environments.

What is MES vs Scada System?

SCADA and MES, though both important for manufacturing, have distinct roles. SCADA acts as the real-time eyes and ears, monitoring equipment and processes with sensor data and alarms. MES, on the other hand, is the brain, using data from SCADA and other sources (schedules, work orders) to optimize production. Imagine SCADA as security cameras and MES as the production manager's office - they work together. SCADA feeds real-time data into MES, allowing MES to analyze and use it for better decision-making, like identifying bottlenecks and ensuring quality control. By working together, SCADA and MES create a powerful system for monitoring, controlling, and optimizing a factory's operations.

Is SAP an ERP or MES?

SAP MES

SAP MES is a software solution specifically designed for discrete manufacturing companies. It acts as the central nervous system of your shop floor, managing and tracking everything in real-time. From materials and machines to production scheduling and quality control, SAP MES provides a comprehensive view. This data allows manufacturers to identify bottlenecks, optimize production processes, and ensure consistent product quality. Additionally, SAP MES integrates seamlessly with other SAP software, such as ERP (Enterprise Resource Planning), for a unified view of your entire operation, from raw materials to finished goods.