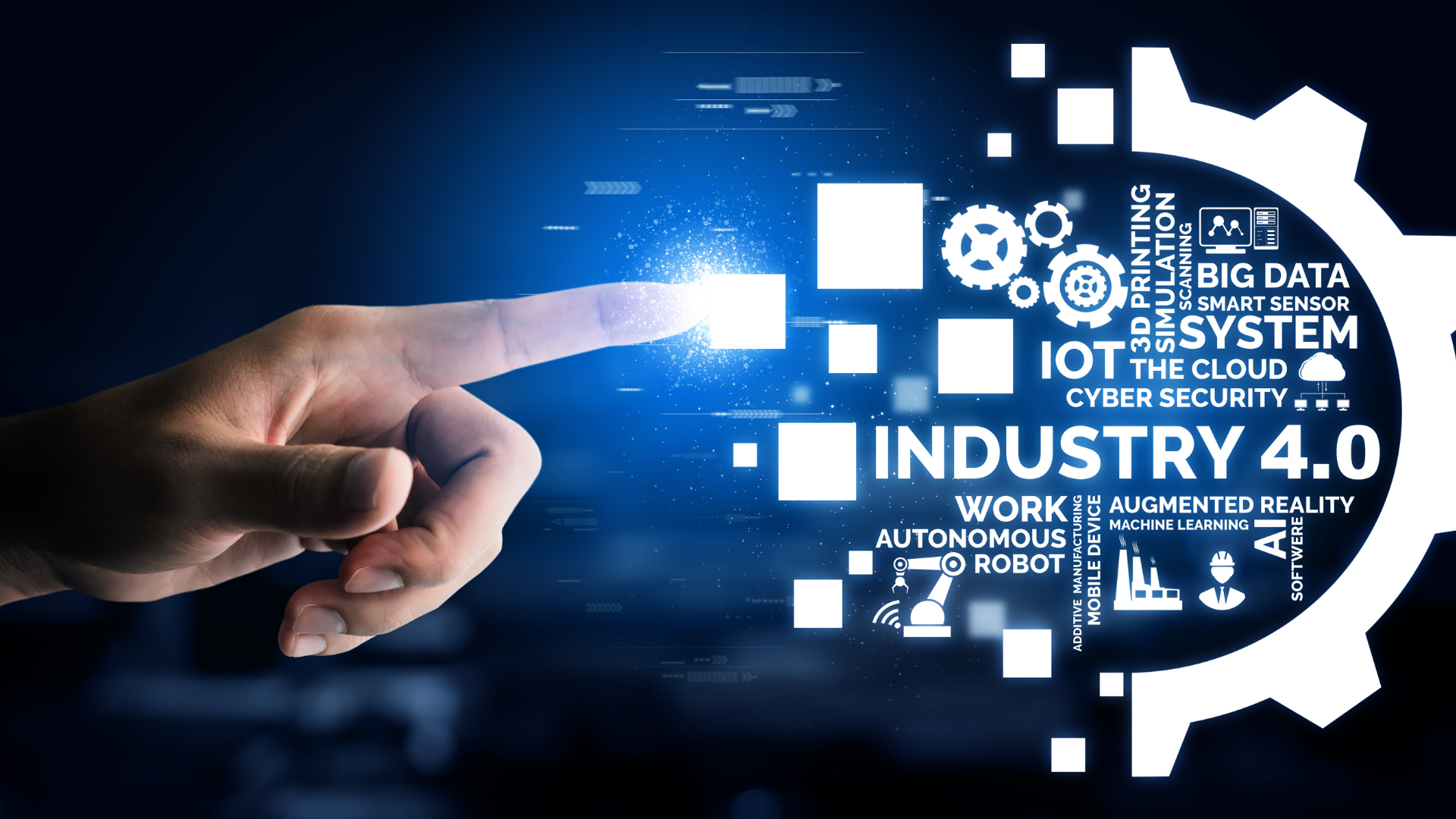

What Is an Example of the Industry 4.0 Revolution?

What Is An Example of the Industry 4.0 Revolution?

The Industry 4.0 benefits has undeniably unleashed a wave of remarkable advancements and unparalleled benefits that have permeated across a multitude of industries. This transformative revolution has not only disrupted traditional business models but has also propelled industries to new heights, driving efficiency, innovation, and competitiveness to unprecedented levels. The profound impact of Industry 4.0 is evident in the seamless integration of cutting-edge technologies such as IoT, artificial intelligence, robotics, and big data analytics, empowering organizations to optimize their operations, streamline processes, and unlock untapped potential for growth and profitability. The undeniable truth is that the benefits brought forth by this revolution are nothing short of revolutionary - catapulting industries into an era of unlimited possibilities where success knows no bounds. The manufacturing sector is experiencing a remarkable revolution, and one notable example of this can be seen in the implementation of advanced technologies. These cutting-edge innovations are transforming the way manufacturing processes are carried out, enhancing efficiency, productivity, and overall performance.

Industry 4.0 Technologies

The implementation of cutting-edge Industry 4.0 technologies has completely revolutionized the way traditional manufacturing processes operate, transforming them into highly efficient and intelligent smart factories. With the integration of automation, artificial intelligence, Internet of Things (IoT), and big data analytics, these factories have witnessed a remarkable shift towards increased productivity, streamlined operations, and improved decision-making capabilities. The transformative power of these advanced technologies has ushered in a new era of manufacturing excellence that embraces innovation and empowers businesses to stay ahead in today's competitive landscape. These groundbreaking technologies empower and facilitate flawless communication and integration between machines, systems, and humans. They revolutionize the way we collaborate and operate by seamlessly connecting these entities, fostering a harmonious ecosystem of efficiency and productivity. With their immense capabilities, they break down barriers and enable a fluid exchange of information, streamlining processes, enhancing decision-making, and propelling us towards unparalleled levels of success.

Industry 4.0 Benefits

The fourth industrial revolution has had a profound impact on the manufacturing sector, leading to a significant increase in both efficiency and productivity. With the advent of advanced technology and automation, manufacturers can now streamline their operations and achieve unparalleled levels of efficiency. This transformative revolution has revolutionized traditional manufacturing processes, allowing for faster production cycles, reduced waste, and optimized resource allocation. As a result, industries are experiencing exponential growth in productivity that was previously unimaginable. Thanks to the implementation of cutting-edge robotics and automation systems, tasks that were once labor-intensive have now been transformed into seamless operations carried out with utmost precision and lightning-fast speed. The utilization of advanced technology has revolutionized industries by eliminating human error and significantly enhancing productivity levels.

Key Impacts of the 4th Industrial Revolution

Furthermore, the cutting-edge Industry 4.0 technologies have revolutionized the manufacturing sector by introducing real-time data collection and analysis capabilities. This empowers manufacturers to make well-informed, data-driven decisions that are crucial for optimizing production processes and achieving unprecedented levels of operational efficiency. By harnessing the power of real-time data, manufacturers can stay ahead of the competition and ensure their operations are always at peak performance. The utilization of Industry 4.0 leads to a significant reduction in downtime, as they are designed to efficiently generate content without any delays. Moreover, these cutting-edge tools ensure improved quality control by consistently producing accurate and error-free content. Additionally, they excel in optimizing resource utilization by efficiently managing workloads and maximizing productivity.

Moreover, it is crucial to acknowledge that the advantages offered by Industry 4.0 go well beyond mere operational enhancements. This revolutionary concept brings forth a myriad of benefits that permeate various aspects of business operations, resulting in unprecedented progress and success. From increased productivity and efficiency to enhanced decision-making capabilities, the impact of Industry 4.0 is truly transformative. By leveraging smart technologies, automation, and data-driven insights, businesses can unlock new levels of innovation and competitiveness in today's rapidly evolving marketplace. The seamless integration of cutting-edge digital technologies empowers manufacturers to not only offer mass-produced products, but also deliver highly customized solutions on a massive scale. This is made possible through the implementation of flexible production lines that can swiftly adapt to changing consumer demands and efficiently cater to individual customer preferences. By harnessing the power of digital innovation, manufacturers are able to elevate their operation capabilities and provide tailored offerings that perfectly align with the unique needs and desires of their customers. Not only does this significantly enhance customer satisfaction, but it also serves as a catalyst for opening up vast new business opportunities.

In a nutshell, Industry 4.0 represents a groundbreaking and revolutionary shift in the manufacturing landscape, where cutting-edge technologies play a pivotal role in driving substantial efficiency gains, boosting productivity to unprecedented heights, and delivering truly innovative solutions for businesses operating across diverse sectors. This transformative wave of technological advancements is reshaping industries in ways that were previously unimaginable.

You might also like