What Is HMI And How It Works

Technology is a crucial part of our society and can't be ignored. Rather than running away from it you should embrace what it offers to make your life easier. As technology develops, do not be left behind. Technology is being implemented on an ever- increasing scale and those who choose not to keep up with the modern practices will have a hard time staying ahead in their field. The question is not whether or not you should embrace technology, but how. If you're already actively embracing technology the best thing to do is learn the ins and outs of it. Learn how to use social media platforms like Twitter, Facebook, and LinkedIn better and more efficiently. Additionally, familiarize yourself with search engine optimization in order to reach a larger audience for your content.

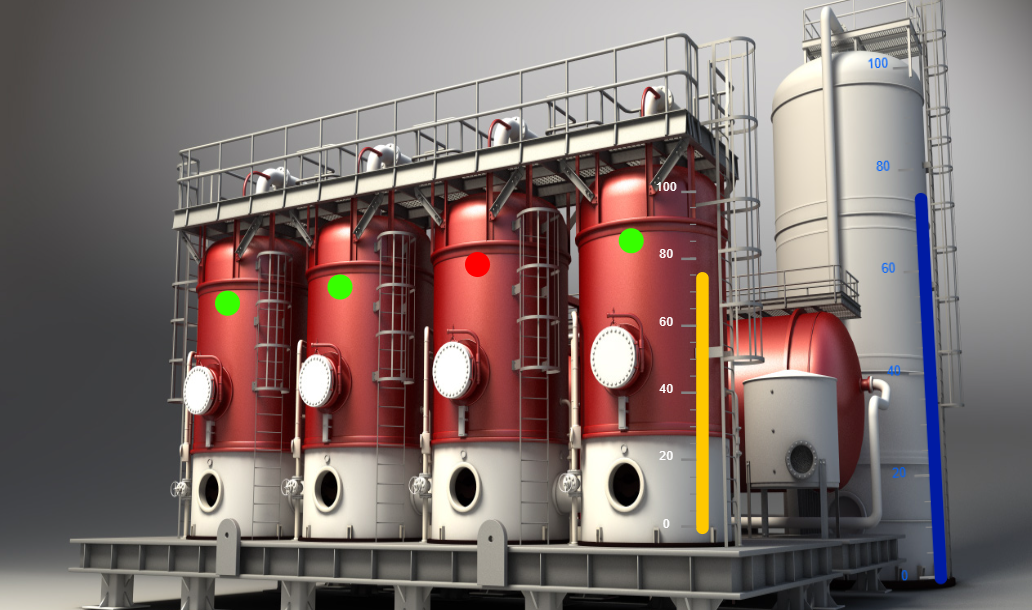

Human-Machine Interfaces are screens commonly used in a number of different industries. They provide information to us and we use these interfaces as a way of monitoring, controlling, and executing certain functions within software applications.

What Is HMI And How does It Relate To SCADA

Human Machine Interfaces are devices that let a human user both interact with a machine and get real-time feedback from it. These screen displays, which are mostly touchscreens, are typically used for managing, monitoring and controlling machinery in more intricate detail.

A common misconception is that HMI SCADA systems and human machine interface systems are very similar. While they do have some overlap, they are not the same thing. An HMI (Human-Machine Interface) is a way of interacting with something that has a visual dashboard/GUI as part of the user interface.

Basically, an HMI is a type of interface that connects to humans and machines. As people become more tech-savvy, we'll rely on HMI's even more to bridge the gap between what we couldn't do without them.

Remote monitoring and other features include:

- Give a clear overview of your data with visualization tools. Different graphs and charts will display x, y and z axes in order to show patterns, trends and relationships.

- Production time, trends, and tagging

- This outline contains a list of KPIs (Key Performance Indicators) to watch.

- This algorithm is useful in terms of understanding production levels, performance and possible disturbances

What Is HMI and How Does HMI Technology Work?

An HMI is a system that operates a machine or device, just like many of the everyday items in our lives. The HVAC in your home needs to be flexible enough so you can regulate the temperature to meet your comfort levels. It's important that you consider how this system can work for you and not the other way around. Some companies use an HMI to control their water storage, wastewater systems and pumps. In some cases, it's used to monitor the SCADA system to make sure everything is running efficiently.

HMIs are often used with PLCs and a number of sensors to collect and display data relating to specific events or criteria of a given system. They can be used for more technical operations such as monitoring, tracking and turning machines on/off (to reduce production costs). It can also include changes to speed of production to achieve stated goals.

Human-Machine Interface displays information in a way that makes sense to the people who are operating them. Operators will be able to view charts, graphs, and other important information that is in a logical order and they can do so without relying on paper records and while also being safe because all data is digitized and centrally located.

Before HMIs were introduced, technicians needed to patrol the plant to make sure everything was running smoothly and to fix any problems they found. It is important to take appropriate precautions when the costs are high and the risks of neglect are substantial. You should always be on the lookout for problems or issues you will have to deal with later. While some problems cannot be detected at all, highly efficient sensors would help you spot many potential issues before they even occur!

What Is HMI And Who Uses HMI Technology?

HMIs are used in a huge range of different industries, they're all over the place. They help engineers interact with industrial machines & systems and give control to companies, so they can optimize their work output.

The following industries can take advantage of HMI (human-machine interface):

- Energy Sector

- Food & Beverage

- Industrial Manufacturing

- Oil & Gas

- Electrical Power

- Recycling

- Transportation

- Water & Wastewater

HMIs are often interacted with by people who perform the following roles: operators, engineers, system integrators, and control system engineers. HMIs provide insight for professionals in those fields.AI helps you to review and monitor computer processes remotely, diagnose problems and see data in a new way.

What Is HMI And How Can We Use Different HMI Applications In Industrial Environments.

There have been plenty of tragedies in the past few decades. Remember the major Exxon oil spill back in 1989? More disasters followed, with most leaks happening because they weren't detected quickly enough. By having a HMI system, these events could be avoided or minimized so that even if there was a leak, it would be quickly detected and fixed before it got out of control.

As systems have improved, new technology has helped to protect against disasters like these. Some the latest systems for managing and monitoring equipment have been equipped with high-tech sensors to detect specific anomalies. With these advanced features, HMI automation is now able to detect small leakages or irregularities in your water system.

If you don't take care of your oil, water, and other vital systems, disaster can strike. Perhaps the most common way major accidents happen is by a spill. Spills lead to a contaminated environment with hazardous materials and have an economic impact on the company. Make sure you always have processes in place to avoid these catastrophes and stay safe!

You might also like